blow molding machine parts name

Zhangjiagang Apollo Machinery Co Ltd ONPLAS Group located in the city of Zhangjiagang which lies conveniently near to the biggest city of ChinaShanghai. ABS molds well after drying.

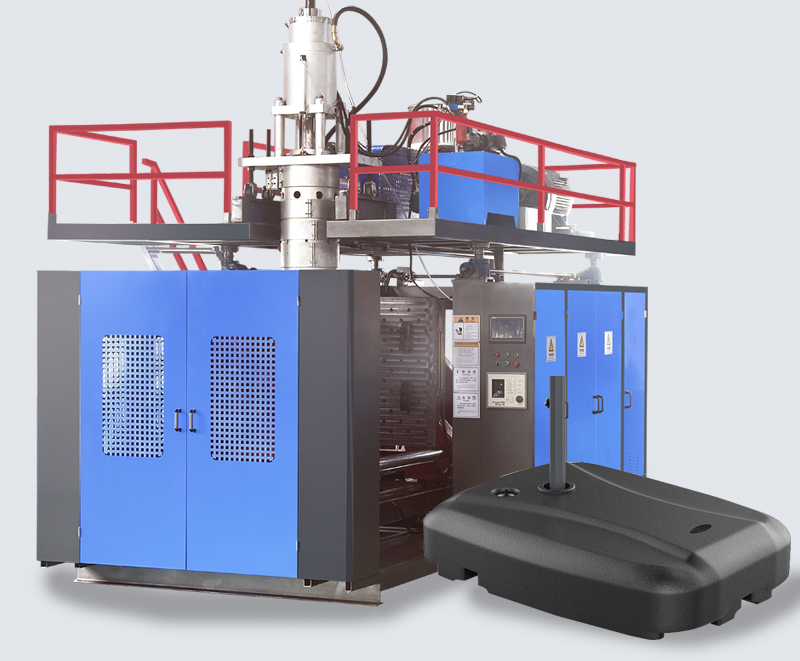

Reservoirs buoys and other items are commonly made with blow molding.

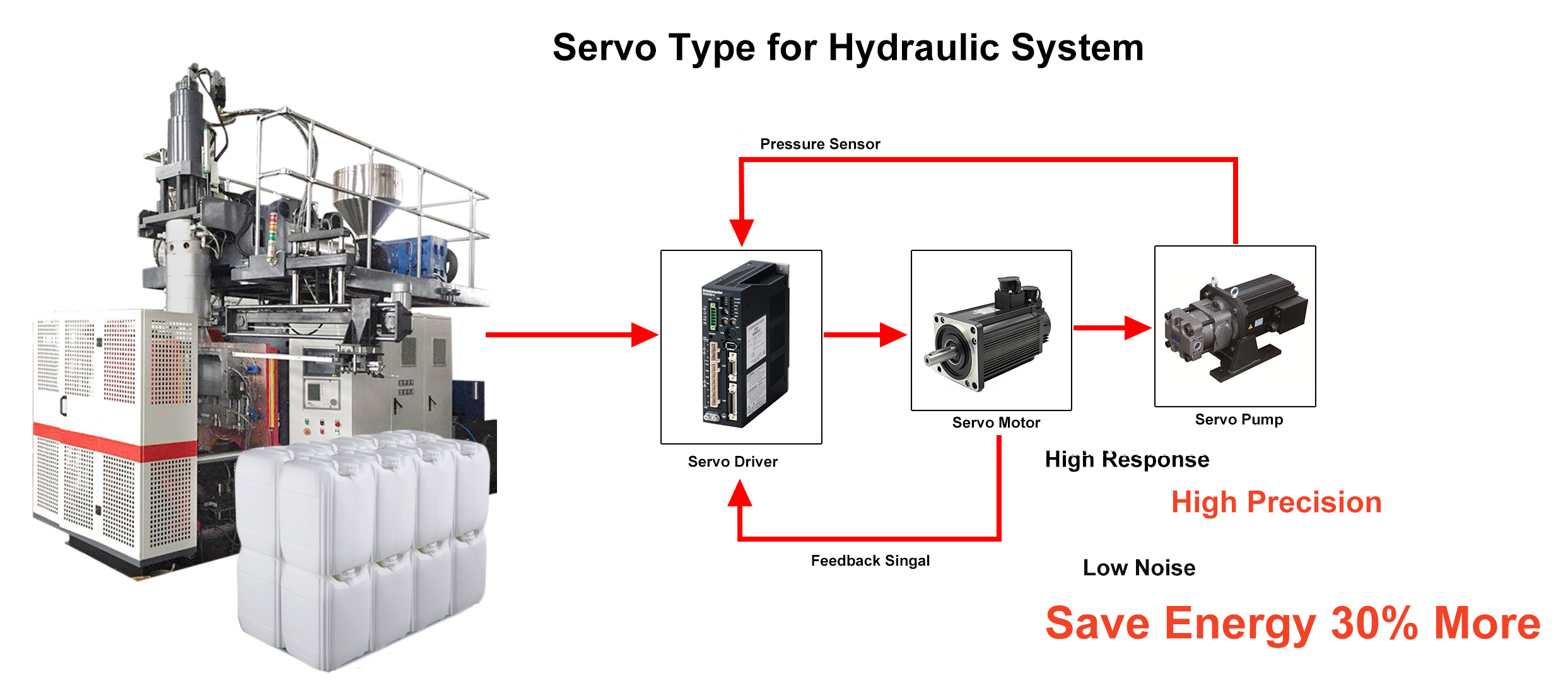

. Looking for used injection blow molding machine parts for sale. The two most common types of blow molding are extrusion blow molding and injection blow molding with many variants related to handling of the thermoplastic melt and molds. Ad Better Innovation Better Packaging.

However parts made from ABS arent as chemically resistant as PE or PP so caution must be used with parts that come in contact with chemicals. In general there are three main types of blow molding. The parison expands outward forming a hollow article in the shape of the cavity.

Once the machine has created the parisons the next step of the blow molding process can begin. Examples of parts produced on this machinery include drums trash cans automotive panels playground equipment and large containers such as Jerry Cans for liquid storage. The first part of blow molding involves working with tubes of molten plastic.

Blow molding machine also known as hollow blow molding machine a kind of rapid development of plastic processing methods. Is a professional manufacturer automatic blow molding machines and bottle blowing machineUnremitting efforts to provide more economical and modern products. Injection blow is ideal for creating small medical and research containers.

Mold and the blow molding process. Shop For All Your Packaging Needs Today. Look no further PlastiWin Capital Equipment has you covered.

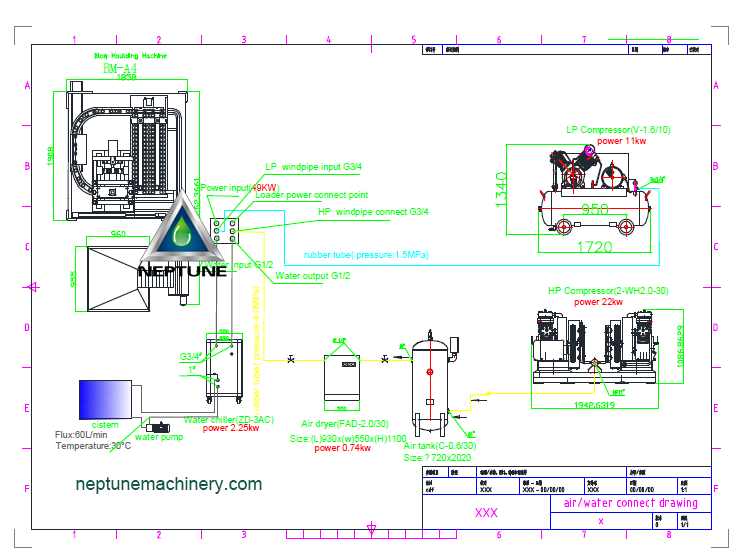

Injection blow molding - The molten plastic is injection molded around a core. Extrusion blow molding EBM is used to produce hollow parts. The tube of melted plastic resin formed by the blow molding die.

Before the extrusion head can form a parison the plastic must be melted. Learn More Small industrial part accumulator head blower The Graham Engineering Mini Hercules cordless head machine is packed with standard functions in compact size for small industrial. Shanghai Duxia Industry and Trade Co Ltd.

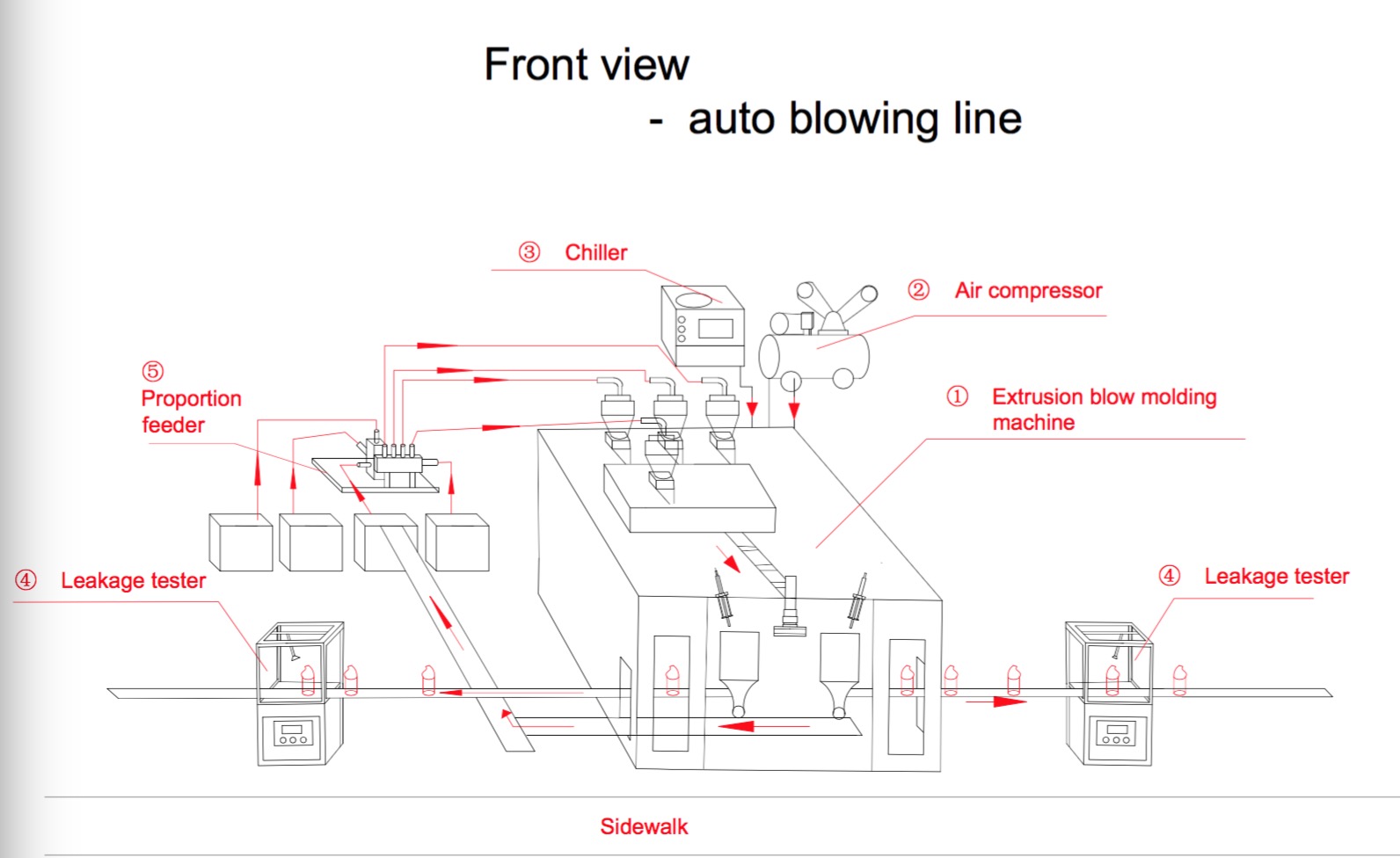

A homogeneous melt flow is essential to produce a perfect blow molded part. In the process a molten tube or parison is extruded into a mold cavity and injected with compressed air. These plastic pellets are meltedplasticized in the extruder.

Plugged or inadequate vents n Clean plugged or dirty vents particularly those along the parting line. Our company occupy an area of 8000 square meters and annual production capacity currently stands at more than 200 sets. The mold should have a fine matte finish to allow air to vent quickly and the parison to conform to the mold surface while it is still hot.

Plastic for extrusion blow molding is usually provided in pellet form also called resin. The metal shape of a manufactured product that fits on the platens of a blow molding machine and contains the plastic under pressure while it cools into the final part shape. Accumulator Head Machinery is used for the extrusion blow molding of large industrial hollow parts.

Sporting Goods A common blow molded product in sporting goods is a plastic bat a plastic ball or another hollow piece of equipment. Poor mold surface n Refinish a poor or worn mold surface. Extrusion blow molding injection blow molding and injection stretch blow molding.

Browse our selection of used blow molding machines. Each blow molding machine is made to change with your business. Multi-million dollar spare parts inventory.

FH Packaging Strives To Create Quality Packing Products Whether It Be Glass Or Plastic. The parison is extruded vertically between the two open mold halves so they can close on the parison and blow pin. Prompt response with spare parts.

Continuous Extrusion Equipment Rotary Wheel Blow Molding Systems Shuttle Extrusion Blow Forming Intermittent Extrusion Blow Forming is a variant of extrusion blow molding. Packaging Customized packaging with Polystyrene keep products safe and blow molding makes hard to create shapes with ease. Trained and experienced employees with access to original design information of your machine.

Pressurized air flows through the blow pin to inflate the parison. 277 depicts an extrusion blow molding process in which a cylinder of semimolten plastic called a parison is extruded downward between two open mold halves. Thermoplastic resin by extrusion or injection molding of plastic parison tube hot or heated to softening state put in split cavity mold closing immediately after ventilation with compressed air within the parison make plastic parison swell and clingy wall in.

Extrusion Blow Moulding Machine. This is the most common type of blow molding and is used to manufacture large quantities of relatively simple parts. Each machine can be modified and upgraded when needed.

Immediate availability of spare parts conversion kits and accessories. Service and Parts available 247 for Blow Molding Machines. All of our blow molding machines are made to last are easy to use and offer quality production.

The parisons will form the base of the extrusion blow molding process no matter what type of bottle part or container you are creating. Reciprocating screw is perfect for molding small parts and is also an Intermittent Extrusion Blow Molding Machine like the accumulator head. It is also used for forming glass bottles.

Blow molding grade ABS is typically opaque and colored for use in electronics housings and small appliances. Parts of Blow Molding. Our goal is to ship our customer orders during the same business day.

When you need parts or service you can call our service line. Blow molding BrE moulding is a manufacturing process by which hollow plastic parts are formed. The blow molding process begins with melting down the plastic and forming it into a parison or in.

Blow Molding An Overview Sciencedirect Topics

Abs Auto Moto Rear Spoiler Blowing Mould Car Spolier Extrusion Blow Molding Mold Making Machine Buy Abs Spoiler Blow Molding Machine Abs Spoiler Blow Mould Machine Abs Spoiler Making Machine Product

Plastic Injection Moulding Machine An Injection Molding Machine Also K Plastic Injection Moulding Machine Plastic Injection Molding Injection Moulding Process

Blow Moulding Machines Blow Molding Manufacturing Blow

Abs Auto Moto Rear Spoiler Blowing Mould Car Spolier Extrusion Blow Molding Mold Making Machine Buy Abs Spoiler Blow Molding Machine Abs Spoiler Blow Mould Machine Abs Spoiler Making Machine Product

Blow Molding Machine Market Growth And Share By 2026

Extrusion Blow Molding Machine Parts Name What Do Parts For The Machine

High Speed Blow Machine Blow Molding Blow Pet Bottle

China Extrusion Blow Molding Machines Manufacturers Factory

The Blow Molding Process The Blow Moulding Process In By Peter Denker Medium

Krones Blow Molding Machine Krones Blowing Machine Krones Moulding Molding Blow Molding Machine

Injection Moulding Of Plastics Injection Moulding Process Injection Moulding Plastic Injection Molding

Blow Molding Machine Yijiu Machinery Is A Manufacturer From China

4000bph Automatic Blow Molding Machine

Ningbo Hairun Yiye Plastic Machinery Co Ltd Plastic Injection Plastic Injection Molding Injection Moulding

Extrusion Blow Moulding Machine Taizhou Huangyan Shengxin Machinery Equipment Co Ltd

Excellent Diagram Of Rotational Molding And Good Article Explaining The Process Molding Plastic Design Mould Design

Abs Auto Moto Rear Spoiler Blowing Mould Car Spolier Extrusion Blow Molding Mold Making Machine Buy Abs Spoiler Blow Molding Machine Abs Spoiler Blow Mould Machine Abs Spoiler Making Machine Product

Blow Molding Machine丨working Principle Process Flow And Common Problems And Solutions In The Blow Molding Process Suzhou Jwell Machinery Co Ltd